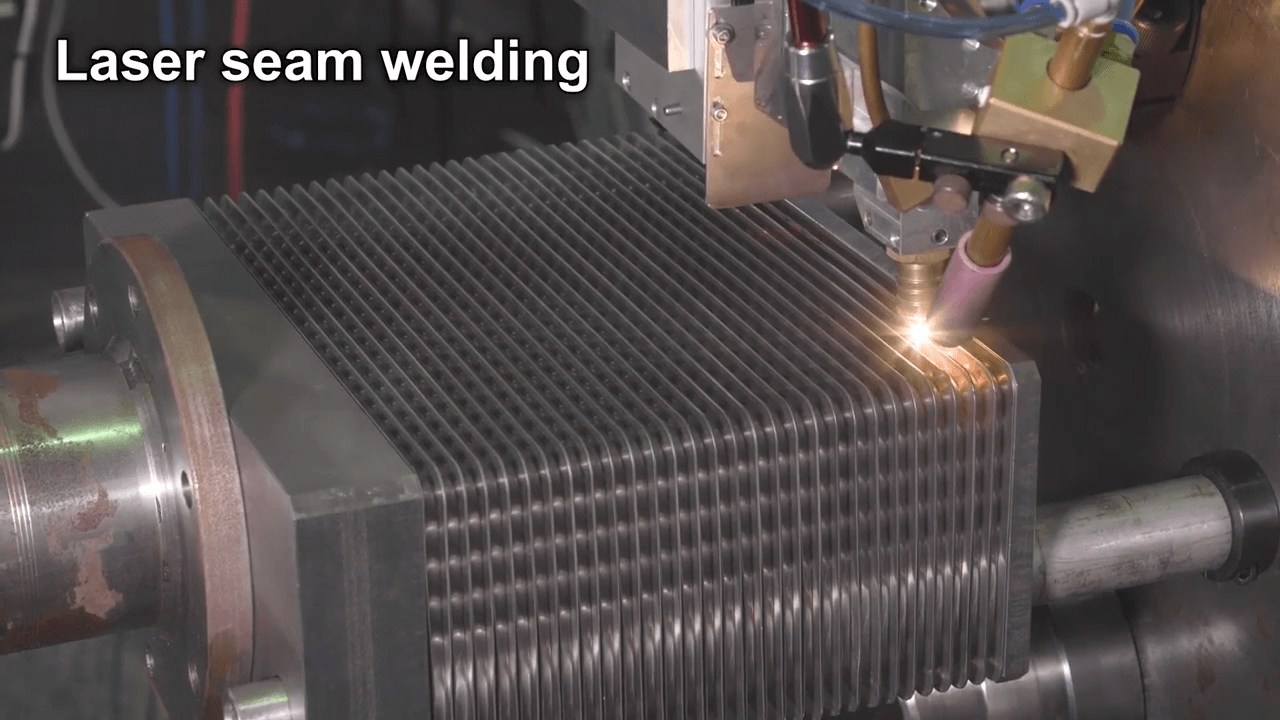

Taiwan SRP Heat Exchangers Inc. collaborated with ITRI ( Industrial Technology Research Institute ) to develop the first Laser welding system for shell and plate heat exchangers in Taiwan. The only company in Taiwan has the ability to design and manufacture shell and plate heat exchangers.

Laser welding is a No welding filler welding technology. It can significantly improve manufacturing speed and product quality. SRP Plate Heat Exchanger was made in a laser welded configuration, making it robust in simplicity, compact design, low weight, flexible capacity extension, and quick/low-cost installation.

Our customers through all over Europe, the United States, Japan, Korea, China, Australia, and most Southeast Asian countries.

Heat exchanger fabrication process:

(caption:The metallographic of welding quality)

Laser Welding Benefits for high quality plate heat exchanger:

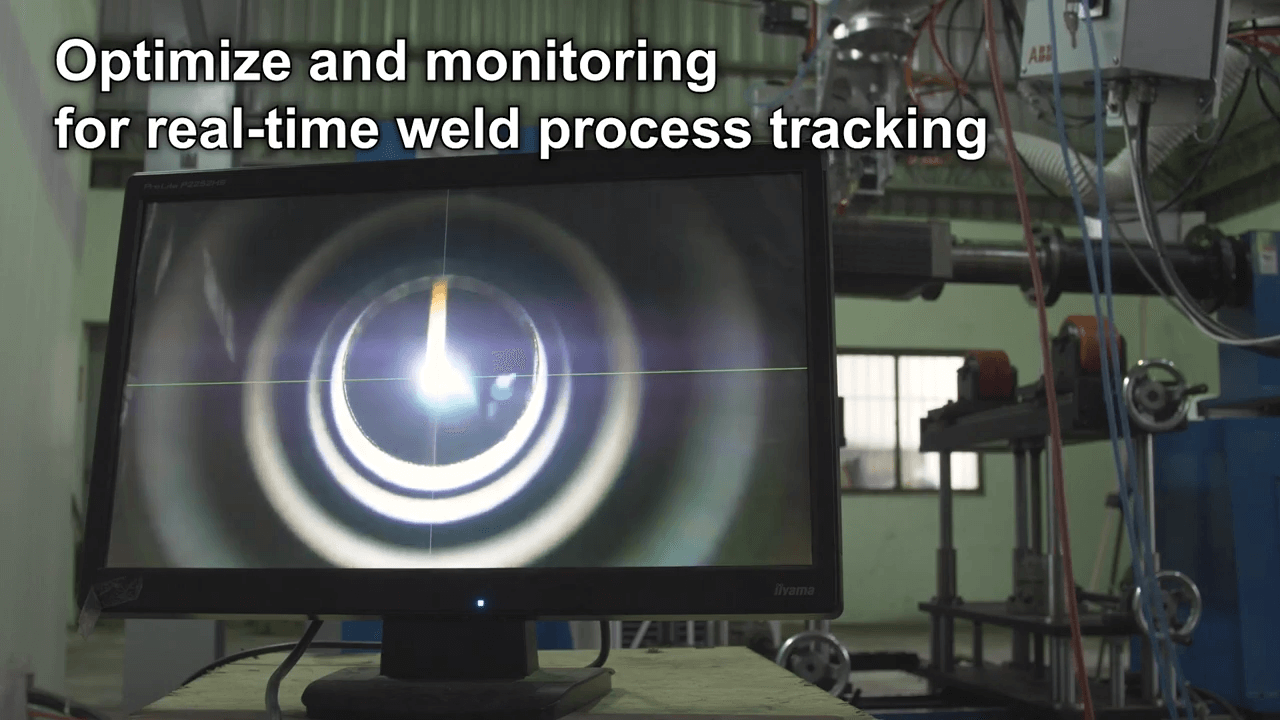

Integrates laser welding system into SRP production line, significantly improving manufacturing speed and product quality.

SRP expertise in the design and manufacturing of shell and plate heat exchangers.

Heat exchangers contain plates stamped from a wide range of high-strength materials.

Features:

Our story begins in 1992 when Swep Taiwan Inc. was founded by Swep International AB Sweden. Swep International AB Sweden sold all shares of Swep Taiwan Inc. in 2007. Swep Taiwan Inc. became a 100% Taiwanese company and changed its name to Taiwan SRP Inc. And fully develop heat exchangers.

Taiwan SRP Heat Exchanger Inc. is here to serve customers with plate heat exchangers, heat transfer solutions and a direct line to the manufacturer from budget to build system.

SRP Heat Exchangers’s experienced team are focused experts in custom fabrication to ensure the right heat exchanger at the right performance to meet your needs and project objectives.

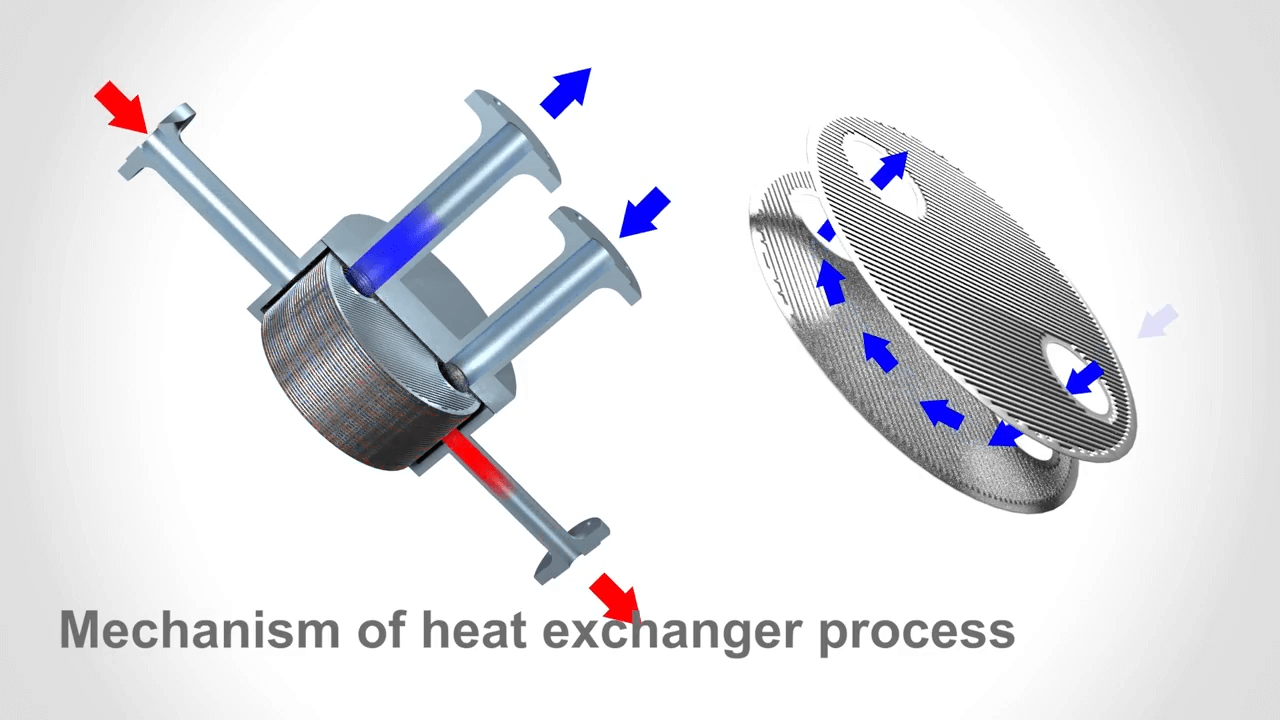

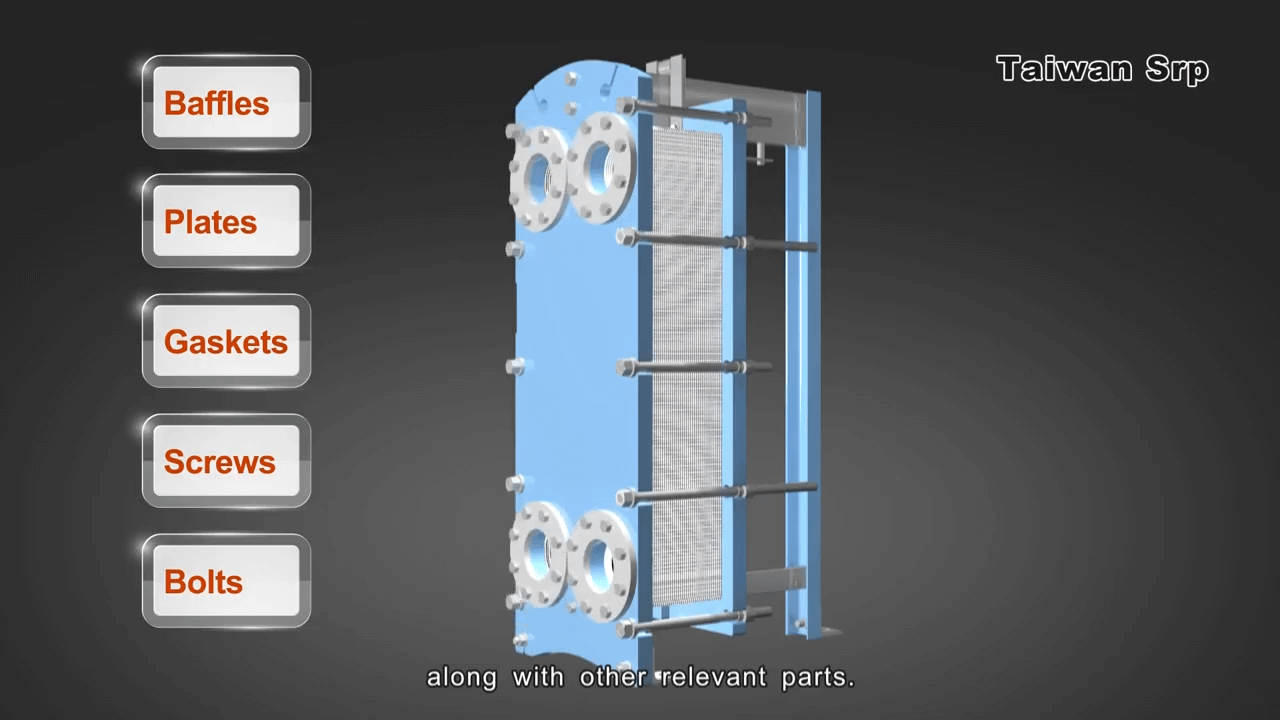

figure. Plate Heat Exchanger Parts

A plate heat exchanger consists of parts such as:

and along with other relevant parts. New developmental technologies use flat flanges for direct tube connection which helps to reduce production costs and time.

Plate heat exchangers are one of the most efficient industrial heat exchange solutions currently in existence.

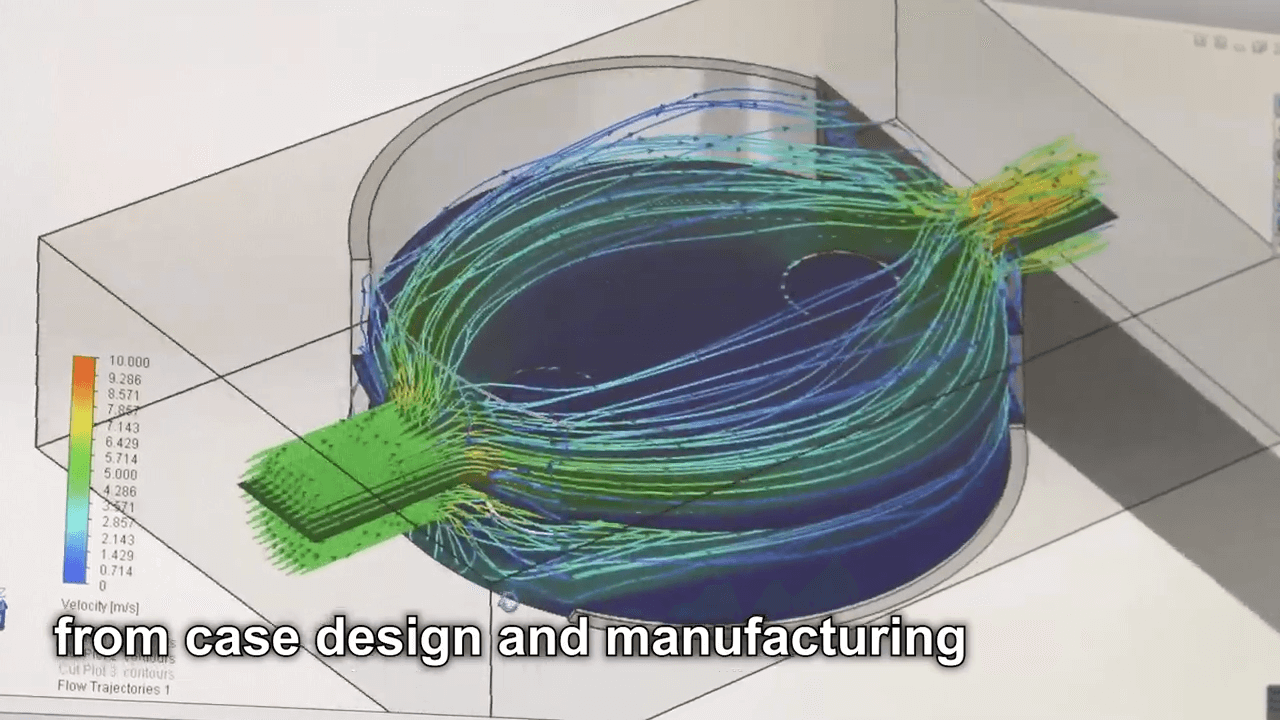

The conception of ideas and R&D are the propellants for creation. Through observations of different industries, we have designed various types of heat exchangers to cater to different needs. Our design and certified project team are experienced to be able to meet the strict requirements of industrial plate heat exchangers.

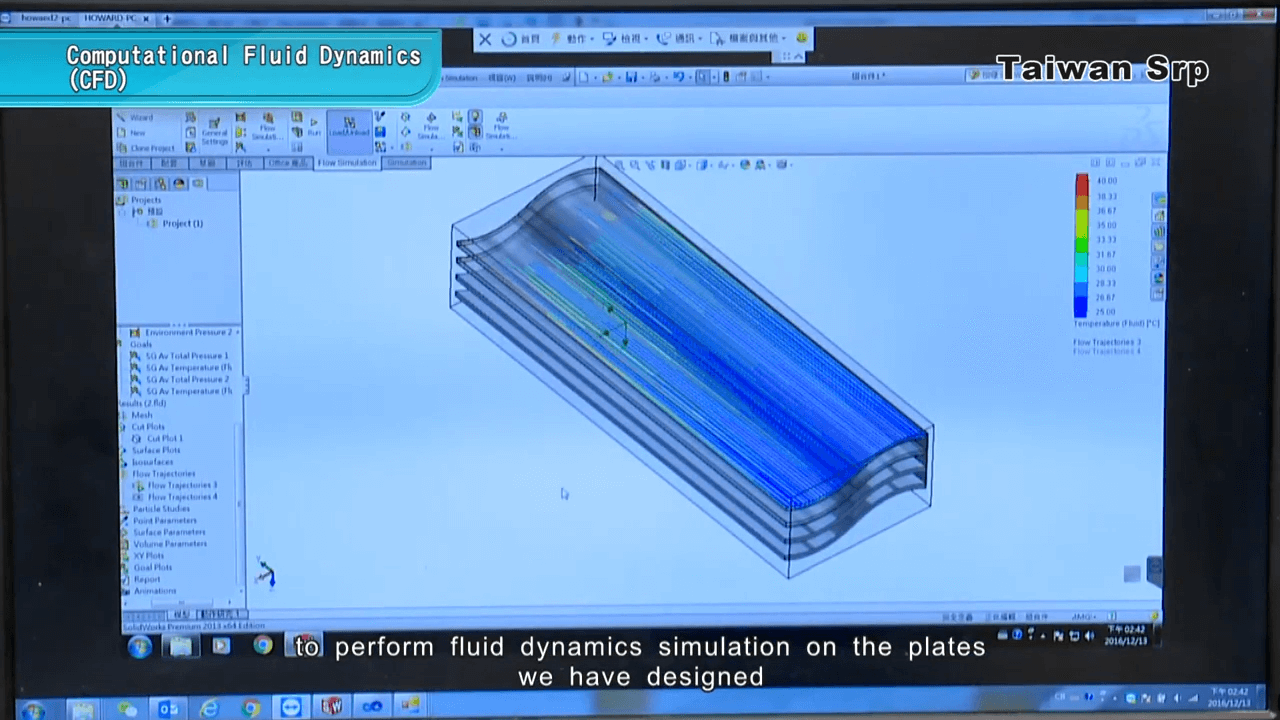

With the ideas in place, the design process follows. First, we use computational fluid dynamics (CFD) software to perform fluid dynamics simulation on the plates we have designed in order to understand fluid movement on the plates and analyze results such as heat transfer efficiency and thermal resistance. These results enabled us to determine if the plate designs are correct.

In order to ensure compliance with pertinent legal regulations and standards, relevant standards were established for specific characteristics, covering plate bearing pressure, plate thickness, specific dimensions for length, width and height, materials used and even the choice of computer models. We use relevant software (pv-elite) to perform the required calculations to ensure thorough planning.

Molds for plate stamping are designed and sculpted based on the results of the CFD analysis.

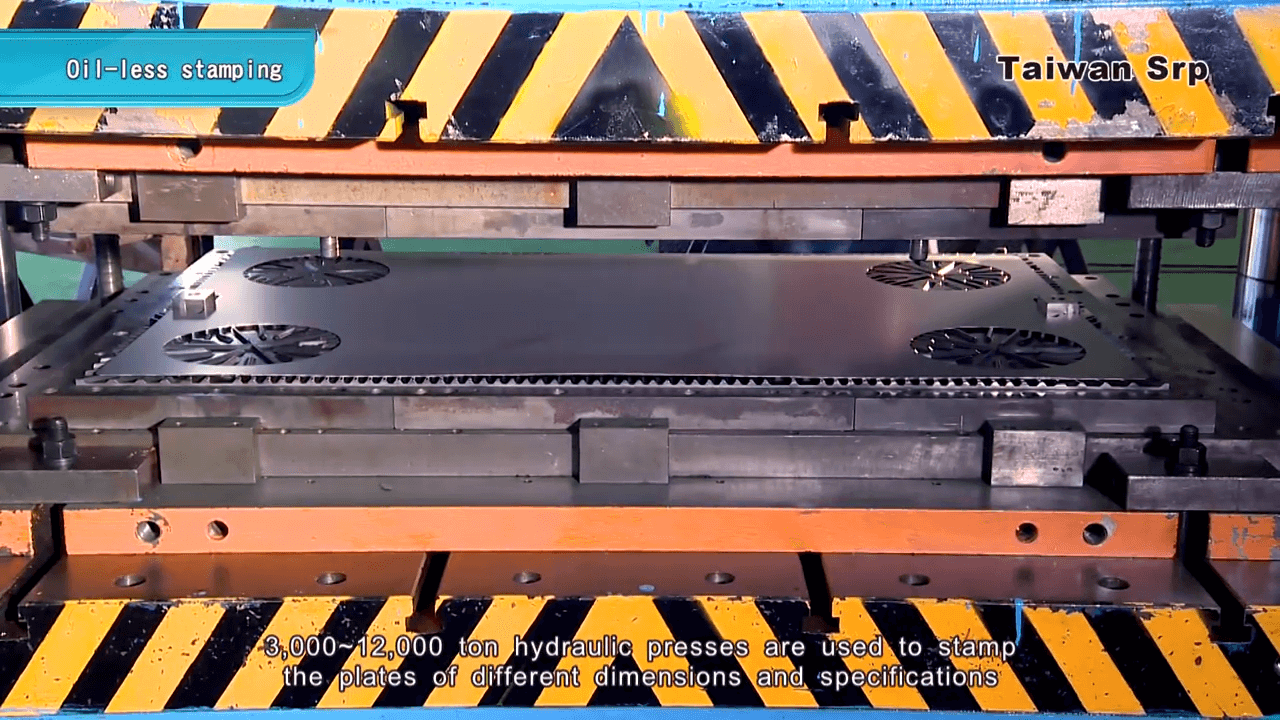

The factory then levels the steel coil and cuts the sheet metal based on the given dimensions.

3,000~12,000 ton hydraulic presses are used to stamp the plates of different dimensions and specifications in oil-less stamping to save the extra step of degreasing the plates, making the process more eco-friendly and time-saving.

The stamped plated are then inspected for their drawing height in order to ensure that the plates are the correct dimensions. Non-conforming drawing height can lead to heat exchanger leakage.

A non-destructive penetration test is conducted on the stamped plates to check for cracks on the plates that could lead to leakage.

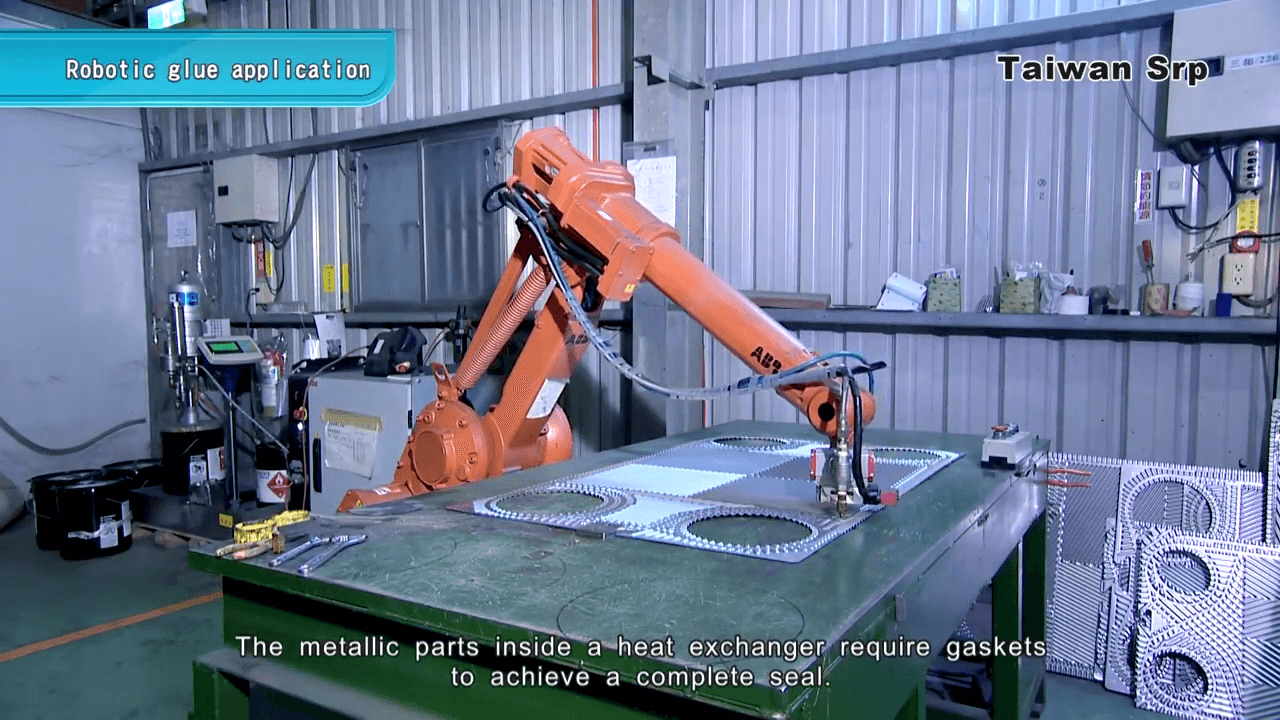

The metallic parts inside a heat exchanger require gaskets to achieve a complete seal. Robotic glue application was adopted to improve the seal between the gaskets and metal and its reliability.

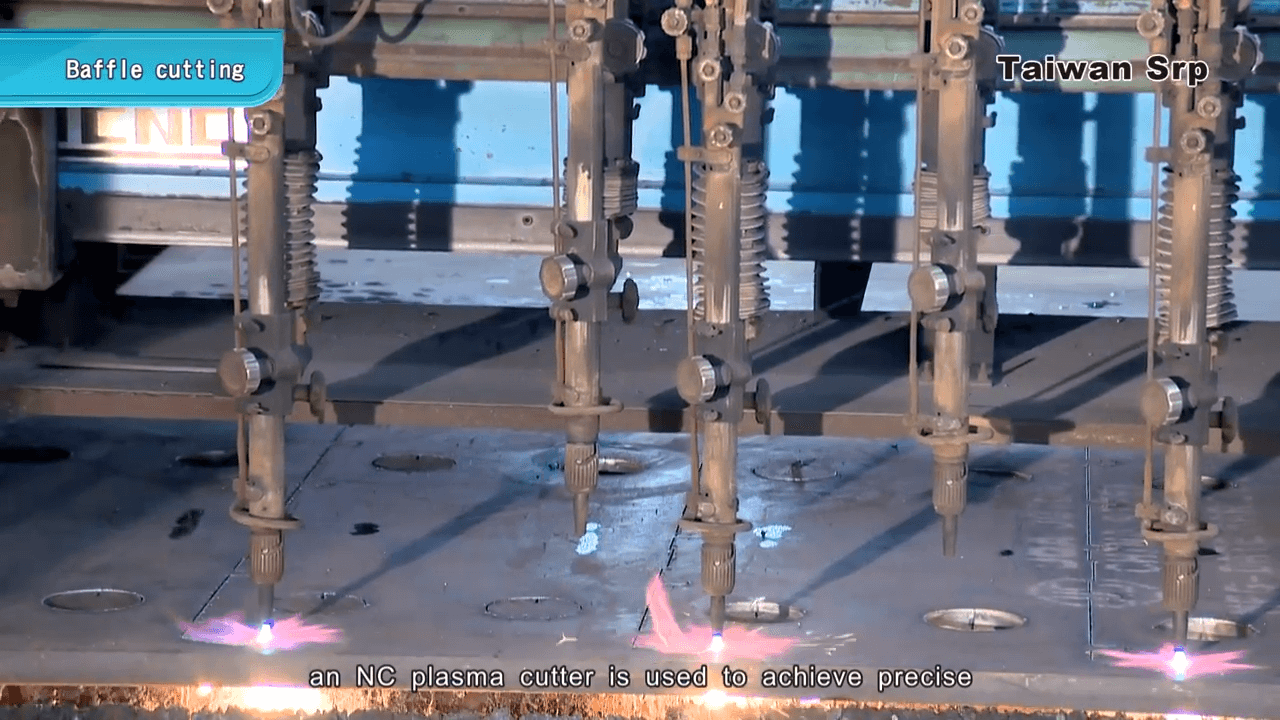

For baffle (Frame) cutting, an NC plasma cutter is used to achieve precise and quick cutting of baffles made with different materials.

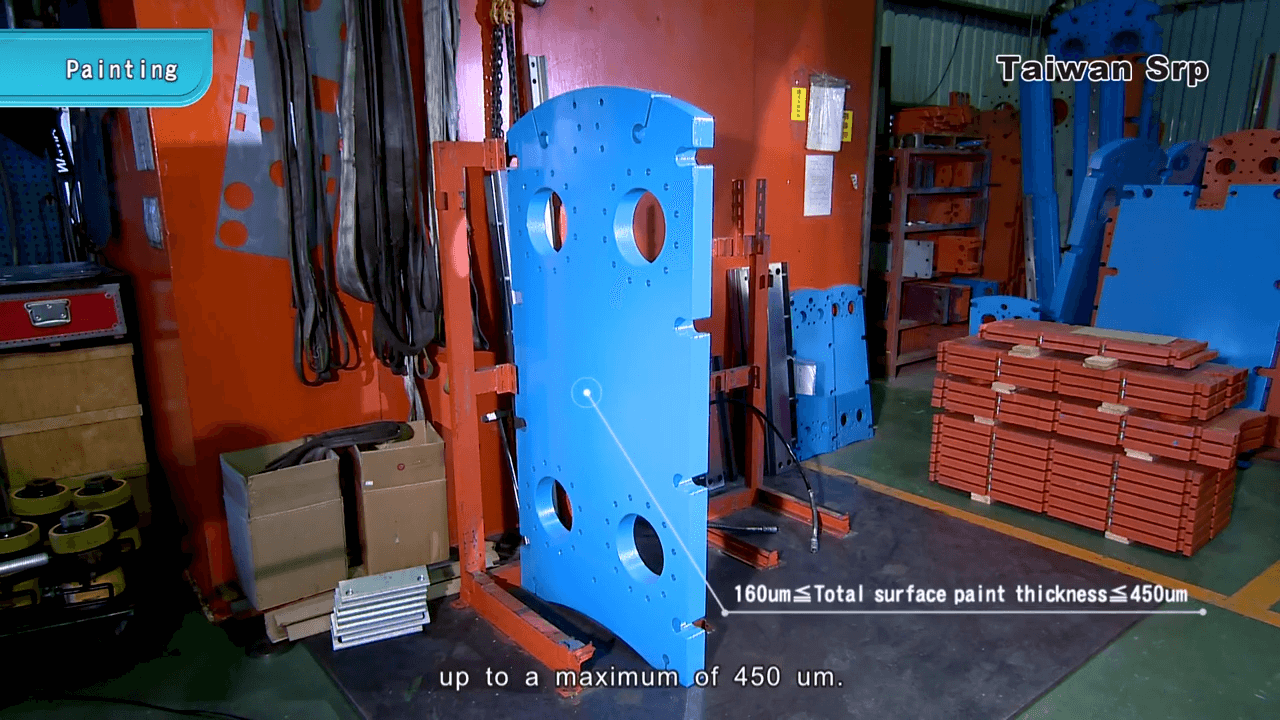

For frame surfaces, in addition to sand-blasting and base-coating, we also apply the surface paint in specific thickness and colors as requested by our clients. Typically, the total surface paint thickness is 160 um, up to a maximum of 450 um. (160 um ≦ Total surface paint thickness ≦ 450 um)

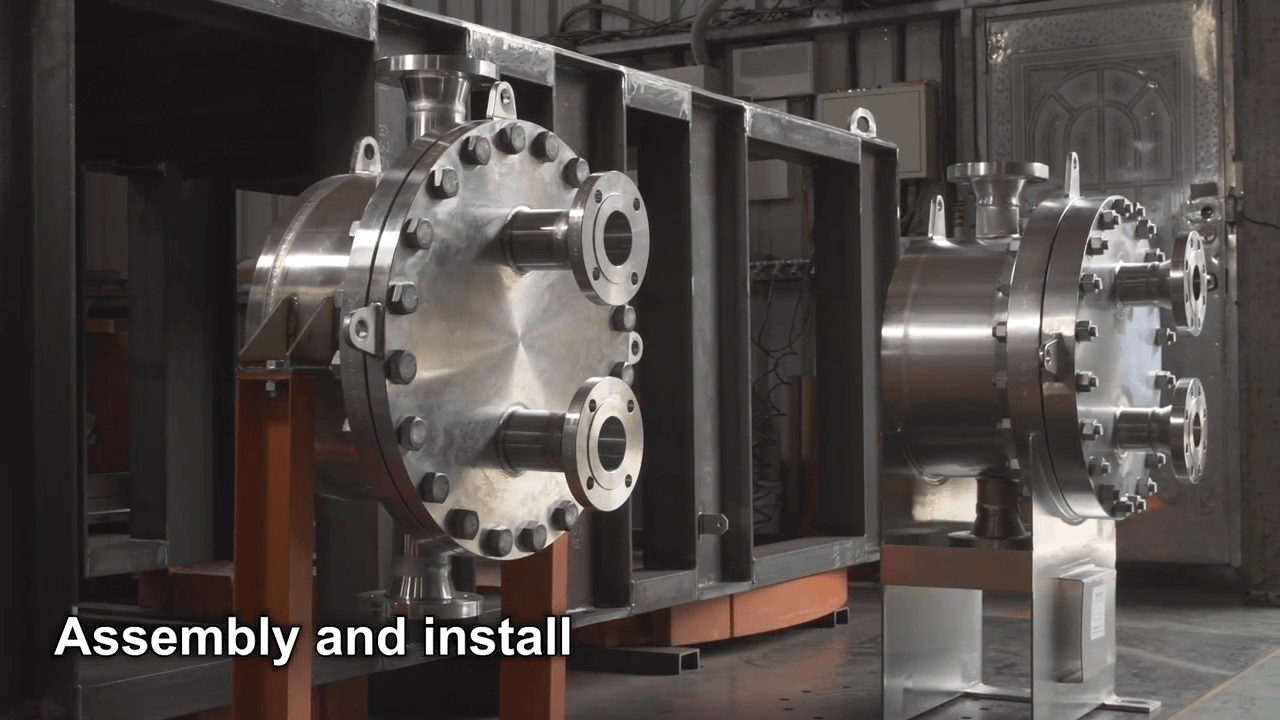

The product then moves to its final assembly, which is done by hydraulic tools rather than manual labor to ensure fast and correct assembly so as to satisfy the design requirements. The purpose of the stress test is to ensure that the product is intact with no leakage. The test involves the application of pressure on one side while the other side has no stress. The stringent tests are performed to ensure product quality.

The finished product is inspected by the QC Department with all tables and forms used during the production collected and compiled as the basis for future maintenance and servicing.

The responsible department arranges for product delivery and ensures that the right products are shipped to the customers.

The SRP Heat Exchanger team has decades of collective experience in Manufacturing, R&D/Product Development, Applications, and Service. We use innovative plate technology and offer personal service to meet your requirements perfectly.